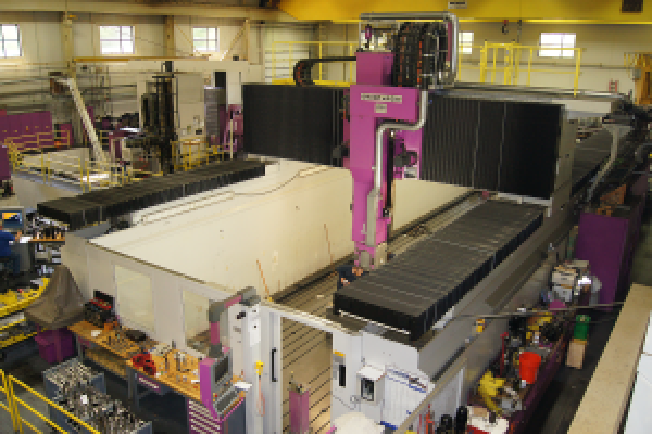

DROOP+REIN FOG

The Droop+Rein FOG series is a powerful concept for complex machining. It offers a range of services, including pre-finishing, to final finishing contour to machining geometries. With a maximum feed rate in dynamic machining, the concept fits for the acceleration and movement of constant masses, irrespective of workpiece weight and size. This high-speed portal machining hub runs high-speed milling. As compared to traditional models, this 5-axis milling with complex surface and high acceleration legacy produces finer and faster finish at maximum accuracy.

Legacy offers Droop+Rein with true accuracy and computer numerical control upgrades for the machine. Heidenheimer CNC family products are employed for the measuring products, which include Anilam and Accu Rite. It also has a fast and highly flexible C-axis, which makes it ideal for multi-functional machining of huge workpieces. Automatic contour deviations billing, tool change or automatic pallet, tool length and diameter measurement are also featured in this series.

Due to a wide range of peripheral devices and components of the integrated system of Droop Rein, they can create a process-oriented and overall efficient system that is personalized to the clients. The high-speed CNC FOG mills are defined by the speed of spindle of more than 18 000 RPM, over 10m/min, and 2.5m/sec2 feed and acceleration rates, respectively. Utilizing this machine, all the manual finishing job is combined with the die and mold machining.

The 5-axis CNC will produce précised and complicated paths. With a little to no hand finishing, it produces a stamping die or a finishing mold. This means a surface geometry of more precision and faster production time and delivery at a lower cost in any alloy or ferrous metal. FOG series is a Droop+Rein supported concept which increases the machine quality and minimizes its time, which is a significant advancement leap in the technology.

connect with us

Ready to bring your project to life?

Consult with one of our industry experts to discuss your project requirements.