OUR TURN-KEY SOLUTIONS

AUTOMATION INTEGRATION

We utilize our core competencies in mechanical, electrical, software and controls engineering, as well as robot simulation

ADDITIVE MANUFACTURING

Offering room & high temperature solutions manufactured from Ultem, Polycarbonate, ASA, ABS, Nylon CF & Dahltram 350CF

TOOLING SERVICES

Offering tight tolerance products manufactured from invar, aluminum alloys, steel alloys and specialty metals

MACHINING SERVICES

Whether its R&D, prototyping, product development or production, our customers can expect top quality and speed to market

overview

Why choose legacy?

- Strong reputation for delivering high-quality products and services that consistently meet or exceed customer expectations

- Our team is dedicated to a continuous improvement culture which helps drive customer satisfaction

- Best value business without compromising quality

- Customer focus at every level of the organization

- Commitment to sustainability and ethical business practices

Collaborative approach

In today’s rapidly changing technological landscape, a collaborative approach is essential to keep up with the demands of the market. Our team of engineers help our customers identify potential issues early in the process, find creative solutions, and help streamline the manufacturing process.

DESIGN PHASE

In-process Manufacturing

Final product

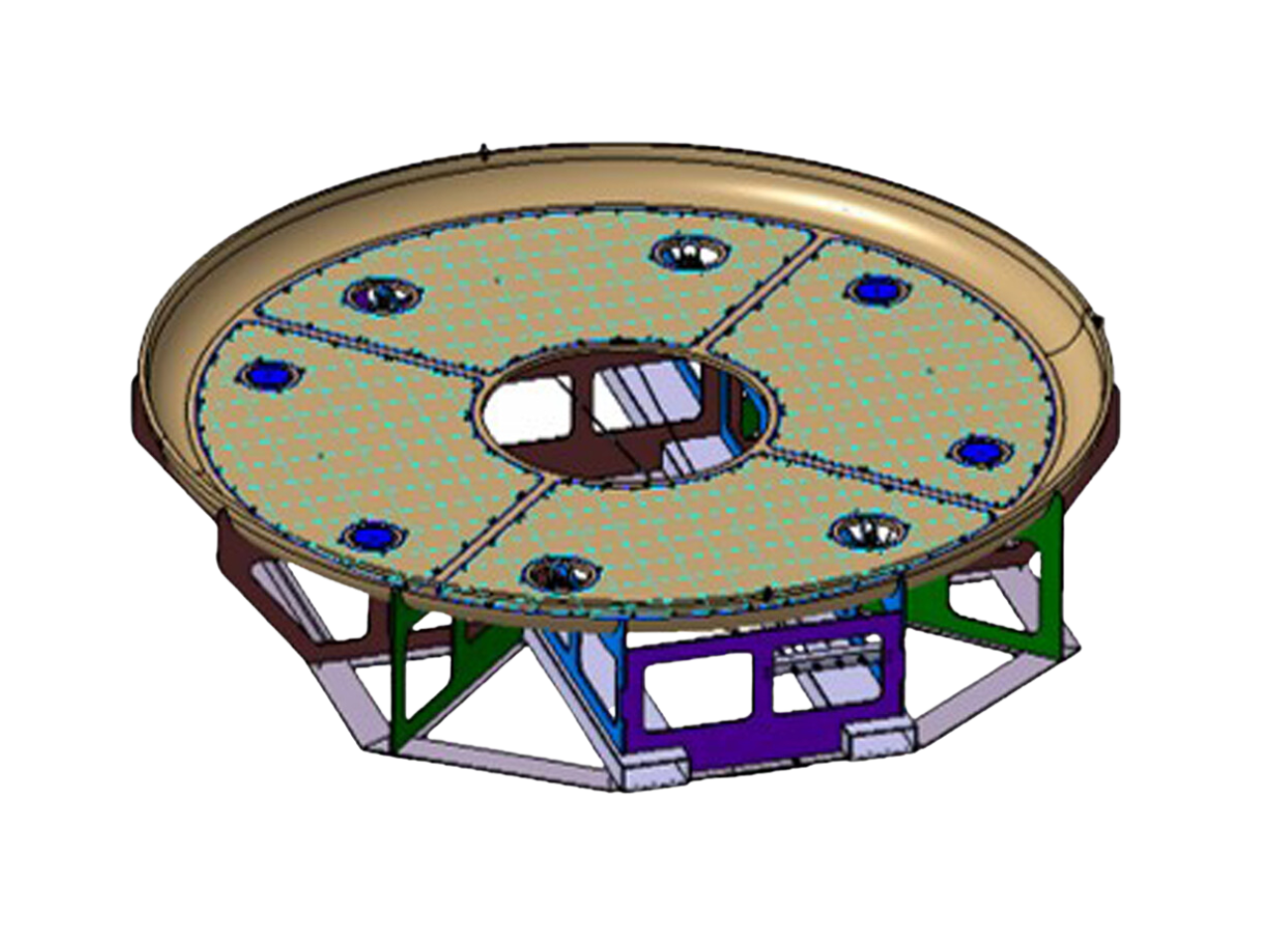

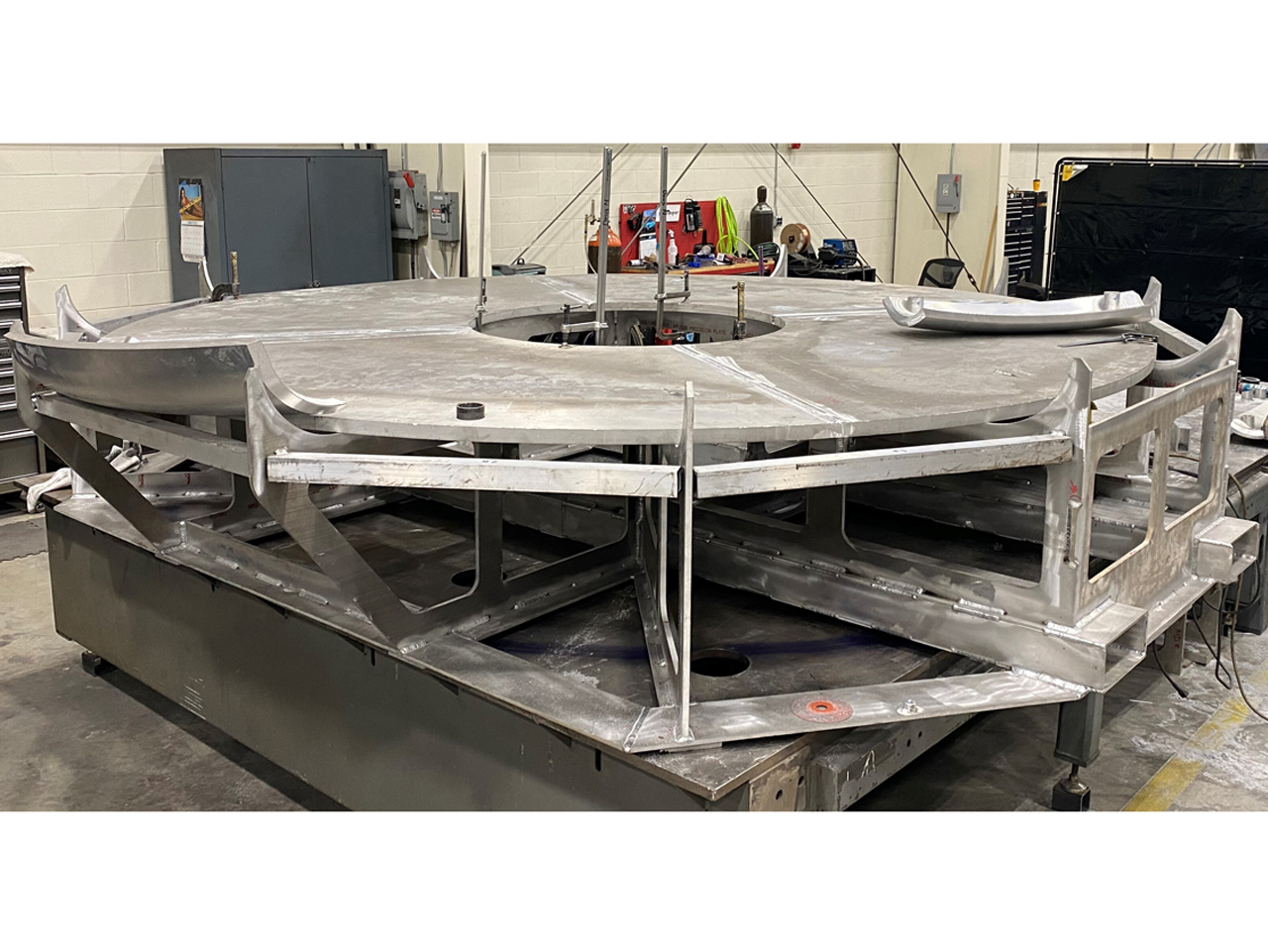

turn-key solutions

design to installation

Legacy Industries custom offerings include tooling services, additive manufacturing, machining services and automation + integration. Our team of over 300 industry professionals have extensive experience in design, engineering, weld fabrication, 5-axis machining, assembly, metrology and installation. Our culture is predicated on 100% first pass quality.

DESIGN & ENGINEERING

STRESS ANALYSIS

FABRICATION

COMPLEX MACHINING

AUTOMATION INTEGRATION

METROLOGY

BUILD & ASSEMBLING

INSTALLATION

connect with us

Ready to bring your project to life?

Consult with one of our industry experts to discuss your project requirements.