A CUT ABOVE THE COMPETITION

The roots of Legacy’s machine shop trace back to 1968. Nearly 50 years ago, Gary Louca founded Louca Mold, which he started as a small machine shop for the automotive industry. The company grew to earn a stellar reputation, and by 2000 became the lead machining vendor in the Detroit area for all large 5-axis aerospace tooling. In 2008, the company expanded its abilities by obtaining the capabilities to machine tooling over 40 feet long. 5 years later, in 2013, Randy Bellestri acquired Louca Mold and Aerospace Machining, where it has since served to play a crucial role in all of Legacy’s operations.

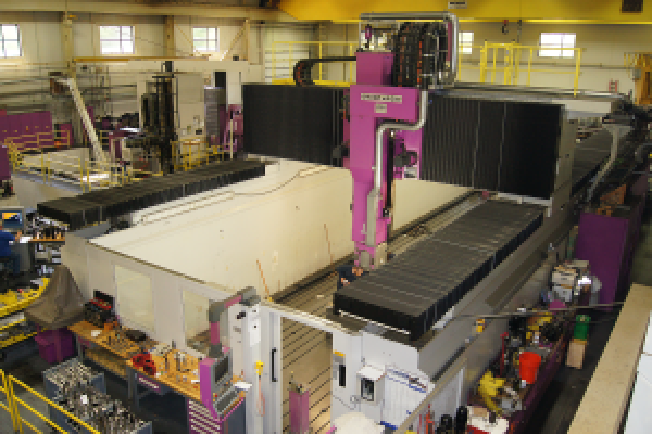

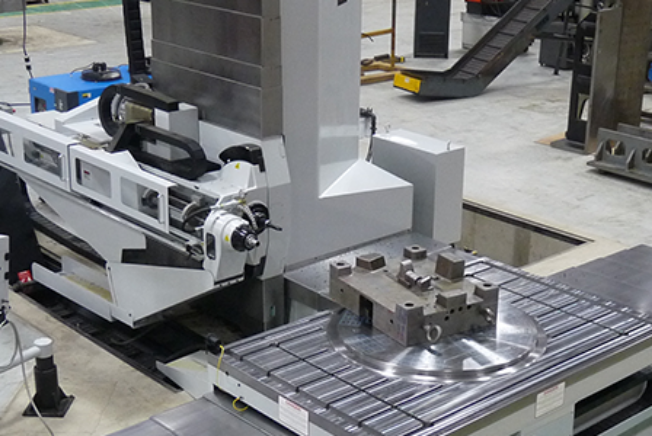

Legacy’s machine shop is equipped with a vast array of cutting edge machines. It contains everything from a Droop and Rein FOG to a G & L Boring Mill. When it comes to aerospace, automotive, and marine machining, we are confident to exceed expectations. Machine fixtures, dies, RTM molds, and assembly tooling, are a few examples of the endless possibilities we can provide with our proud team of machinists who are meticulously equipped to master precision machining processes. You can always expect top-quality products, as well as speed to market and on-time deliveries. We understand that no matter how great a job we can do for you, if it isn’t there on time, it’s not worth anything to the customer.

Are you ready to learn more about Legacy’s unrivaled machining capabilities?

Our experts are more than happy to give you any additional information at

MACHINING CAPABILITIES

| Machine Type & Model Number | Number of Axis | X” | Y” | Z” |

|---|---|---|---|---|

| Droop and Rein FOG | 3+2 | 180 | 108 | 50 |

| Droop and Rein FOG | 5 | 624 | 216 | 68 |

| Droop and Rein FOG | 5 | 576 | 216 | 68 |

| Droop and Rein FOG | 5 | 267 | 118 | 59 |

| Droop and Rein FOG | 5 | 780 | 192 | 78 |

| Drop and Rein TF | 3+2 | 216 | 133 | 59 |

| Drop and Rein TF | 3+2 | 216 | 133 | 59 |

| Fadal VMC 6535 | 3 | 65 | 35 | 35 |

| Fadal VMC 6535 | 3 | 60 | 30 | 30 |

| Fadal VMC 6535 | 3 | 80 | 30 | 30 |

| Fidia K199 | 5 | 65 | 36 | 33 |

| Fidia D321 | 5 | 120 | 80 | 48 |

| Fidia D321 | 5 | 120 | 80 | 48 |

| Fidia D321 | 5 | 120 | 80 | 48 |

| FPT | 3 | 360 | 120 | 60 |

| FPT | 5 | 360 | 120 | 60 |

| FPT | 5 | 360 | 120 | 60 |

| FPT | 5 | 360 | 120 | 60 |

| G & L Boring Mil | 4 | 98 | 78 | 31 |

| FPT Ronin | 5 | 236 | 78 | 49 |

| FPT Ronin | 5 | 158 | 78 | 49 |

| FPT Dino Max | 5 | 138 | 98 | 51 |

| FPT DX350 | 5 | 138 | 99 | 52 |

| FPT Dino | 5 | 118 | 48 | 43 |

| FPT Dino | 5 | 118 | 48 | 43 |

| ProMac | 5 | 118 | 118 | 59 |

| Kenichi | 5 | 98 | 86 | 40 |

| Kenichi | 5 | 98 | 86 | 40 |

| Kenichi | 5 | 98 | 86 | 40 |

| Mecoff Umill | 5 | 66 | 55 | 49 |

| Mecoff Umill | 5 | 66 | 55 | 49 |

| FPT Stinger | 5 | 48 | 38 | 24 |

| FPT Stinger | 5 | 44 | 40 | 24 |

| Parpas | 3 | 137 | 63 | 60 |

| Sigma | 3 | 118 | 55 | 40 |

| Droop & Rein | 3 | 110 | 55 | 49 |

| Doosan 750L | 3 | 85 | 30 | 26 |

| FPT Raid XL | 3 | 79 | 44 | 32 |

| FPT Raid XL | 3 | 79 | 44 | 32 |

| FPT Raid XL | 3 | 79 | 44 | 32 |

| YCM | 3 | 68 | 30 | 28 |

| YCM | 3 | 68 | 30 | 28 |

| YCM | 3 | 68 | 30 | 28 |

Modular Assembly has taken off in many industries and a big interest in this type of system is on the rise. These systems are flexible and customizable, designed mainly for decreased product lifecycles and a growing need for improved agility.

connect with us

Ready to bring your project to life?

Consult with one of our industry experts to discuss your project requirements.